Shop

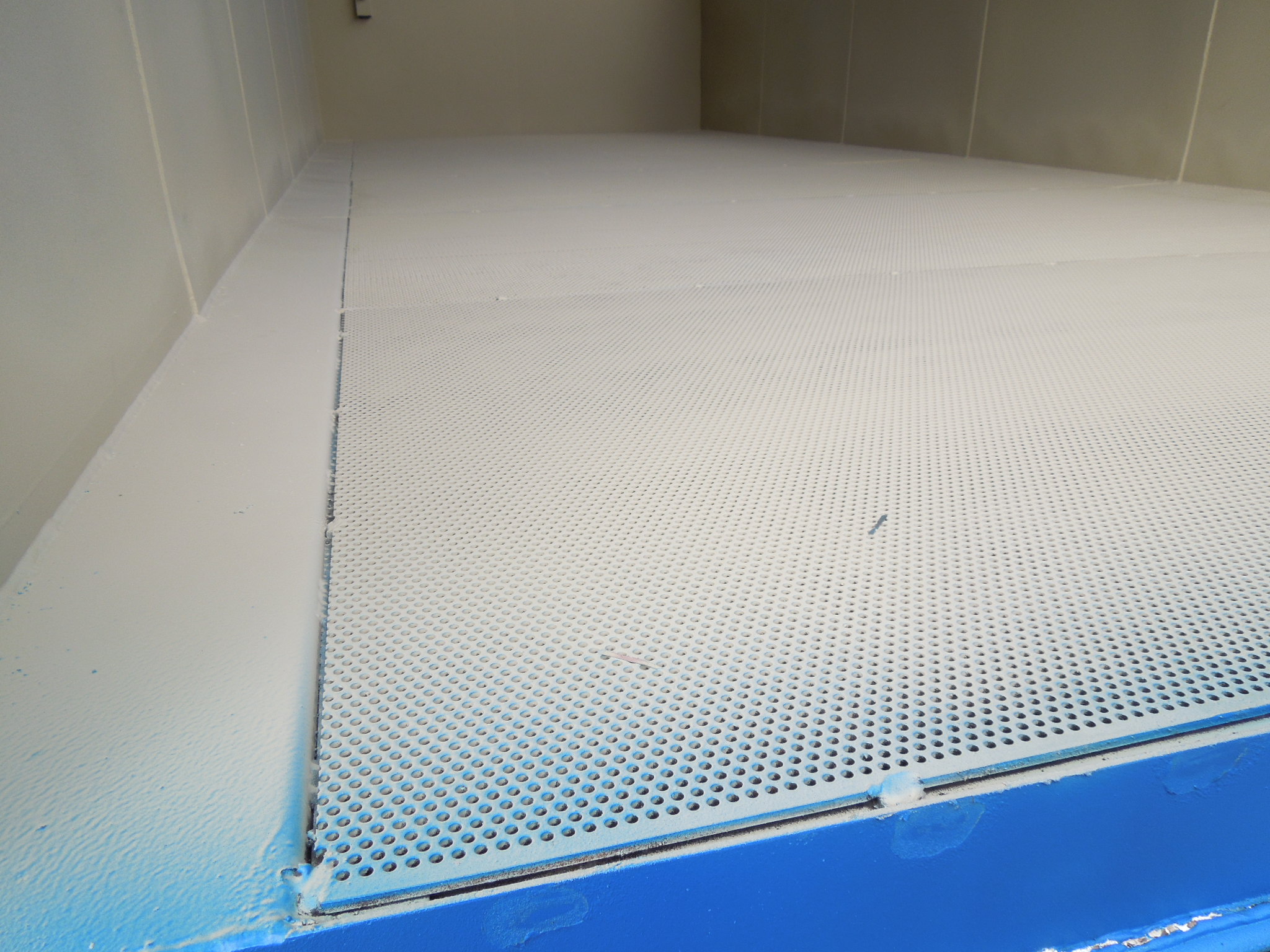

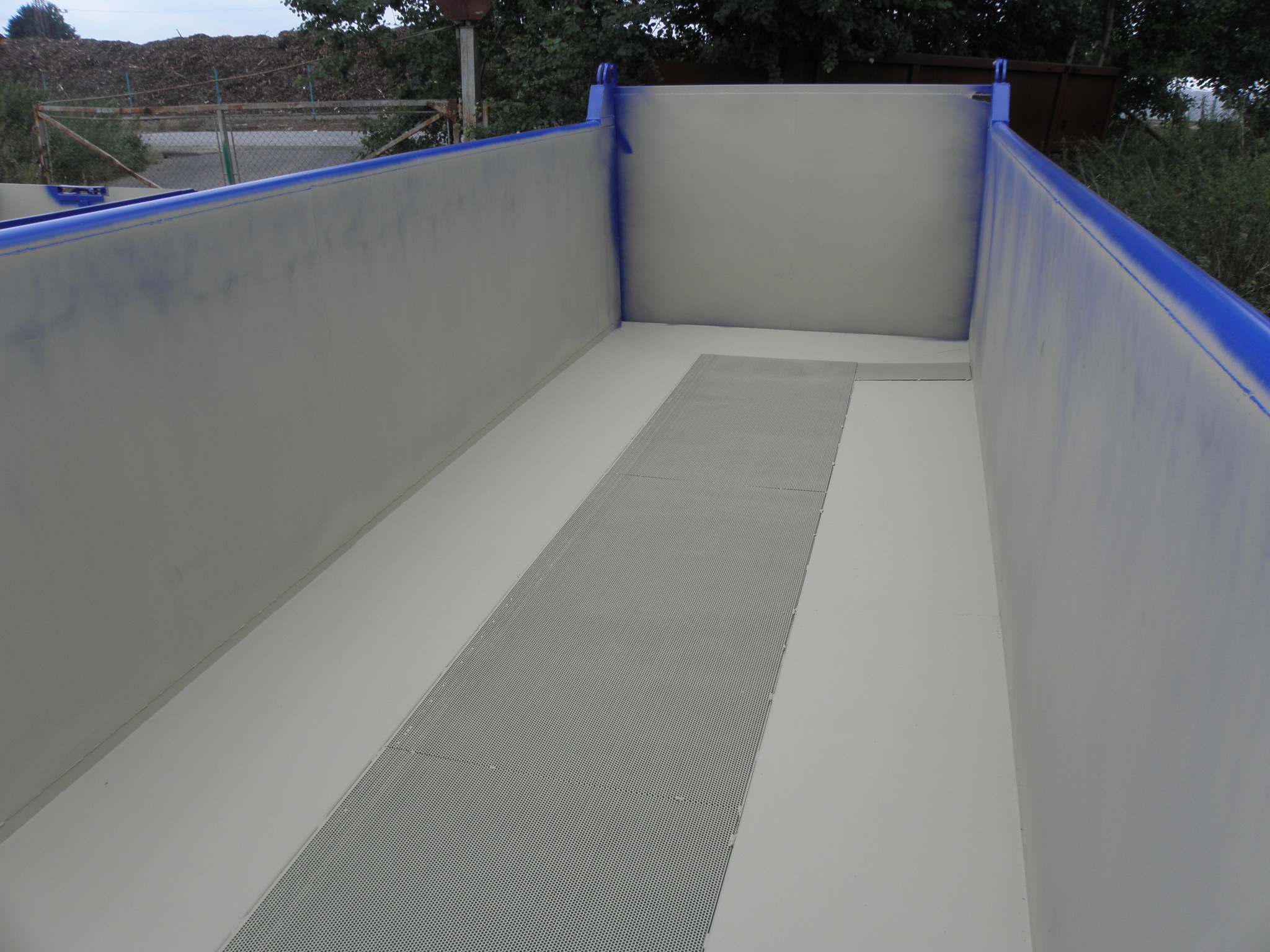

double floor – PERFORATED METAL SHEET

ECO-containers are used for the storage and handling of liquid and solid substances that are in closed barrels and packages. The double floor covered with a perforated sheet metal serves as a catch basin for any drips. Before handling the container, we recommend draining the liquid from the floor with the drain valve so that it does not leak when the container is tipped against the door.

TECHNICAL PARAMETERS

- container manufactured according to DIN 30 722.1

- feed hook, height – 1570 mm – diameter 50 mm – quality of the material S 355

- supporting frame – INP 180 – outer dimension 1065 mm – reinforced in the middle

- floor – metal sheet, th. 5 mm, quality of the material S 235 JR

- walls – metal sheet, th. 3 mm, quality of the material S 235 JR

- side wall reinforcements – distance 500 mm, 625 mm, 750 mm, 1000 mm

- 1x longitudinal reinforcement from height 2250 mm

- upper profile – square section or tube

- connecting the wall to the floor – 45°or 90°

- two steel rollers with lubricators and bronze cases

- door with or without rubber seal:

a) double-winged door with upper hooke type “S” – protection against unintentional opening

b) single door with rivet seal – tighten on pressure screws

c) tipper door

- roof:

a) fixed saddle roof

b) steel winch lifting roof

- waterproof welded floor including waterproof test

- drain velve

- primer 60 my – outside and inside of the container

- one-colour top coat synthetic varnish 40 my – only inside of the container, in RAL, according to the customer’s wishes

- load capacity 15,000 kg

- all materials used are certified

- volume:up to 40 m3

on request:

- different thicknesses and quality of sheet metal

- courting eyes

- raised floor at the door